Advantage  > PRODUCT INTRODUCTION

> PRODUCT INTRODUCTION

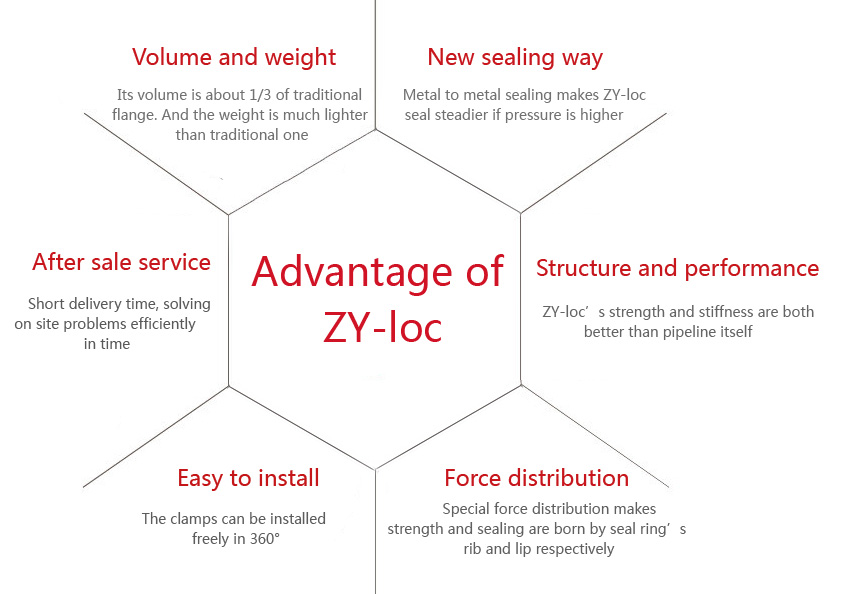

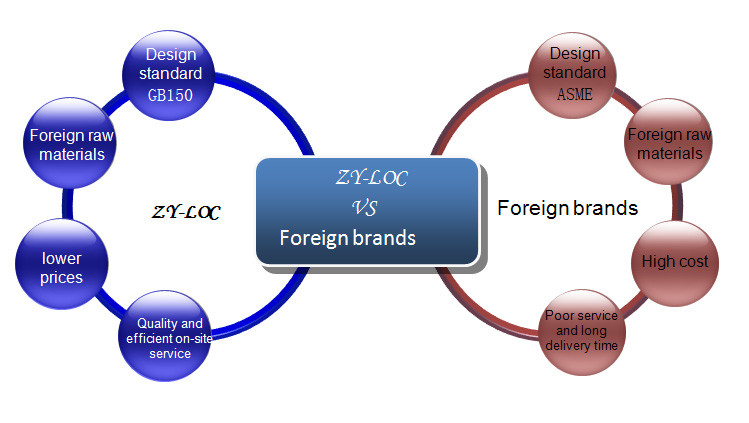

? As we all know, all standards in the world refer to US ASME when we first set. China’s GB150 is no exception. Considering there is a big gap in China’s mechanic material’s metallographic structure, P, S content, synthesized mechanical properties, and corrosion resistance, we are sound on goose when we formulate GB150, so security coefficient is high, allowable stress is low and big corrosion allowance. ZY-LOC is designed based on GB150, but the most important part is imported from US and west Europe. So it is safer than similar products aboard.

? Products aboard allow 10-15% plastic deformation (They think it is safe and reliable), while ZY-loc’s design is 100% elastic deformation. ZY-loc is safer and ZY-loc’s compensation ability for deformation is higher.

? There are only US Grayloc, UK Vector, Italy G-loc and China ZY-loc four kinds of similar products. Though basic principle is the same but the sealing angle, width, and protector against scouring are all different. They can’t be exchanged with each other.

? Zy-loc delivery time is shorter. Usually it is 2 months, because clamps which cost longest time before have had moods and clamps, precision forgings, are in high quality and nice in surface. However, foreign products need 6 months or even longer.

? Zhiyuan can solve all kinds of manufacturing and engineering problems on site, ie Erodos coal-direct-to-petroleum project, Sichuan Tianhua BDO project, Xinjiang Meike BDO project are the best on site examples.

? Zy-loc price is only 1/3 of foreign products.